It’s been a little while since I wrote Part I of this series (well, okay, it’s been six months). To recap: Over the winter I discovered that the compressor in my ’87 325is was clearly fubarred. I found a local E30 guy on Craigslist selling a/c stuff he’d yanked from his car to turn it into a track rat, including a compressor of unknown provenance. Normally, I’d never do something like that—air-conditioning work is intensive enough that I generally start with new components—but I thought that this time I’d take the risk.

It’s been a little while since I wrote Part I of this series (well, okay, it’s been six months). To recap: Over the winter I discovered that the compressor in my ’87 325is was clearly fubarred. I found a local E30 guy on Craigslist selling a/c stuff he’d yanked from his car to turn it into a track rat, including a compressor of unknown provenance. Normally, I’d never do something like that—air-conditioning work is intensive enough that I generally start with new components—but I thought that this time I’d take the risk.

The E30 guy was thrilled. As far as he was concerned, I was paying him twenty bucks to take two boxes of junk out of his garage.

When I removed the old compressor and looked inside the lines, I saw a small amount of black particulate matter. It wasn’t the Black Death, the tsunami of tar-consistency sludge that affects certain cars, particularly 1990s Ford products, but it was enough that the lines clearly needed to be flushed. I pulled the evaporator out of the console and flushed it, along with the condenser and every rubber and metal hose, with mineral spirits.

Now, Facebook friend Trent Cole, a pro, had warned me, “You’re kidding yourself if you think 30 seconds of pressurized mineral spirits is going to get that system clean. If this was a customer’s car and I needed to get the a/c working and not have it come back as a warranty repair, I’d replace every single a/c component on the car.” Point understood and ceded—but this is part of the joy of working on your own car. You can try stuff and see what happens.

While I had the evaporator out, I replaced the expansion valve with the proper valve for R12, as the car had never been converted to R134a and I was not going to do it now. As you can read about in my first book, if you’re going to convert an old a/c system from R12 to R134a, for it to work well, in my opinion, you really need to replace original serpentine-flow condenser with the biggest parallel-flow condenser you can fit in the nose, and I wasn’t going to do that on the E30. I was content to flush it, throw a used compressor and a new receiver-drier in it, and see what happened.

So I flushed everything out, installed the new drier, filled the system up with the right amount of mineral oil, pressure-tested it with nitrogen, and didn’t find any obvious leaks—that is, the needles on the pressure gauges sat steady, and there was no audible hissing sound anywhere. The next step would normally be to evacuate it and charge it up, but it was winter.

Actually, that’s not true.

Not the winter part—that was true. But ideally, the next step in a/c repair is to leave the pressurized nitrogen in it for a day, two days, or even a week if you don’t need to use the car. Just leave the gauges hooked up and see if the system loses pressure; if that pressure gauge drops 10% every night, you’re actively lying to yourself if you think there’s not a leak. When I checked the pressure a few days later, I found that it was down by half. Dam it’s leaking.

And that’s where I left it six months ago in the dead of winter.

So now, with the clock running out on a very steamy August, I thought it was the time to finish this project. I re-pressurized the system to about 150 psi and sprayed every connection with Big Blu, the detection-optimized soapy fluid made especially for this task. Leaks are most often found at connections—hose-to-hose, hose-to-component—but they can also occur in the big flat expanse of the condenser itself, or at the compressor main seal, or—worst case—in the evaporator up under the dash where you can’t spray. You work methodically, spray everything you can, and watch.

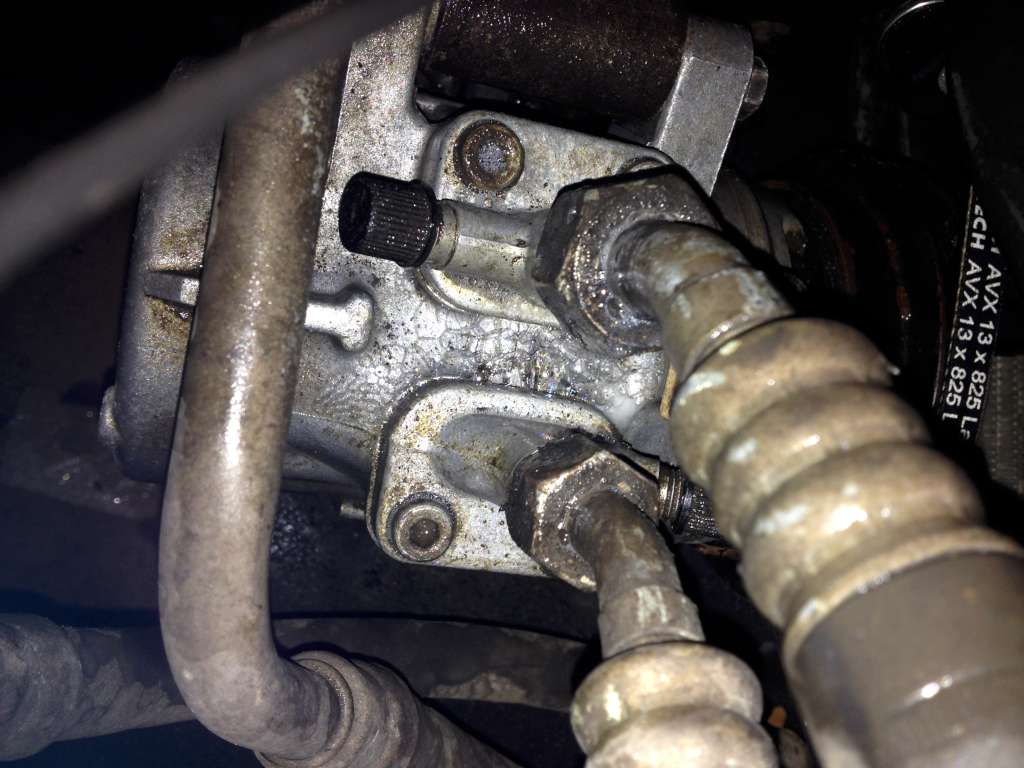

I soon saw bubbles leaking from a place I’d never encountered a leak before: under the aluminum flanges that bolt to the top of the compressor, where it hosts the fittings for the two hoses. It made sense that there would be O-rings under there; I’d just never had to change one there before.

I couldn’t quite get enough clearance and leverage to remove the Allen-key bolts holding on the flanges while the compressor was in the car, so I yanked it. I got the flanges off (one each on the suction and discharge sides), took the O-rings to a local auto-parts store, matched them up, cleaned everything, installed the O-rings, tightened the flanges back down, reinstalled the compressor and the hoses, pressurized it again, sprayed the area again, and saw no more bubbles.

It was tempting to think, “I found and fixed the leak, so now I can evacuate the system and recharge it”—but since this is a car I’m basically not using, I had the luxury of allowing time to do my work. I could let it sit overnight at a minimum, so I pressurized it again to 150 psi and re-checked it in the morning.

The pressure had fallen to 135.

Now, as you know from your high-school chemistry, as temperature goes up, pressure goes up, and vice-versa, so it’s not unreasonable that when you check the pressure on the gauges in the morning, in a cool garage, it may be slightly lower than it was the night before in a hot garage. So I waited another 24 hours and checked again.

It was down another 15%. The system had another leak.

This is why, to sound like my hero John Muir—the author of The VW Idiot Manual, not the naturalist—for a moment, you can do this sort of work better than anyone else in the world, including a pro, because it’s your car, it’s sitting in your space, and you don’t need to rush to get it out of a work bay and get the next car in. So I worked the Big Blu again, and it wasn’t too hard to find Culprit #2: It was leaking at one of the fittings on the receiver-drier.

I took the connection apart, cleaned the threads, put a good coating of Nylog (air-conditioning thread and O-ring sealant) on it, reassembled, pressurized, and waited.

Day One: Good.

Day Two: Still good.

Day Three: Oh, yeah. I’m calling it.

I hooked up the vacuum pump, and 90 minutes later, I had the system evacuated. Now that I knew it was tight, I shot the requisite amount of Freon into it, and it blew cold. I drove the car around in the 90-degree heat, and it still blew cold.

Looks like I lucked out.

Now, Trent Cole may very well be right; in a few months, the expansion valve may plug up with mung I couldn’t flush out. And again, this is very much the exception for me; when I do a from-scratch install or a rejuvenation of a long-dead system, I cut zero corners.

But it was nice to roll the dice on this one, and at least for now, have them come up sevens.—Rob Siegel

Rob’s first book, Memoirs of a Hack Mechanic, and his new book, The Hack Mechanic Guide to European Automotive Electrical Systems, are available through Bentley Publishers, Amazon, ECS Tuning, and Bavarian Autosport—or you can get personally inscribed copies through Rob’s website: www.robsiegel.com.